The production of lithium-ion batteries increased by over 80 times in the period 2000-2018, with about two-thirds of those batteries being utilized in electric vehicles (EVs). Moreover, experts predict that by 2030, the demand for batteries will have increased 17-fold as a result of the anticipated growth of EVs.

Given the fast-growing EV market, an obvious question arises: can EV Li-ion batteries be recycled?

Cobalt, copper, lithium, and nickel are among the elements used to make an EV battery. These rare metals have a high environmental impact associated with their mining. Thus, most of the greenhouse gas emissions from the production of a new battery come from mining and refining operations. Additionally, ‘dead’ battery-safe disposal can increase the overall expense of this type of battery.

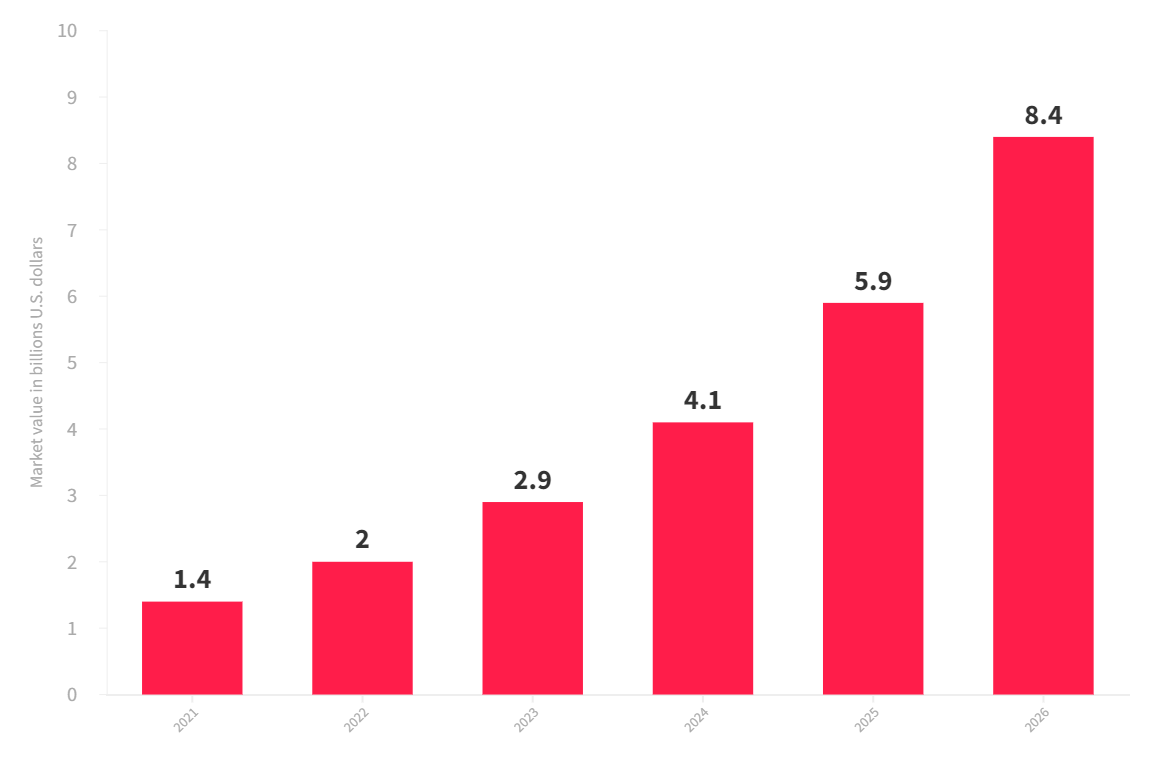

In view of the impressive growth rate of the EV Li-ion battery popularity in mind, while the recycling market for these was worth a modest US$1.93 billion in 2022, by 2035, this is expected to reach US$30.5 billion.

At the same time, estimates show that by 2025 EVs will make up 20% of the global car market. Despite not being as harmful as nickel–cadmium batteries (Ni–Cd), lithium-ion batteries do contain substances that must not be released into the surroundings.

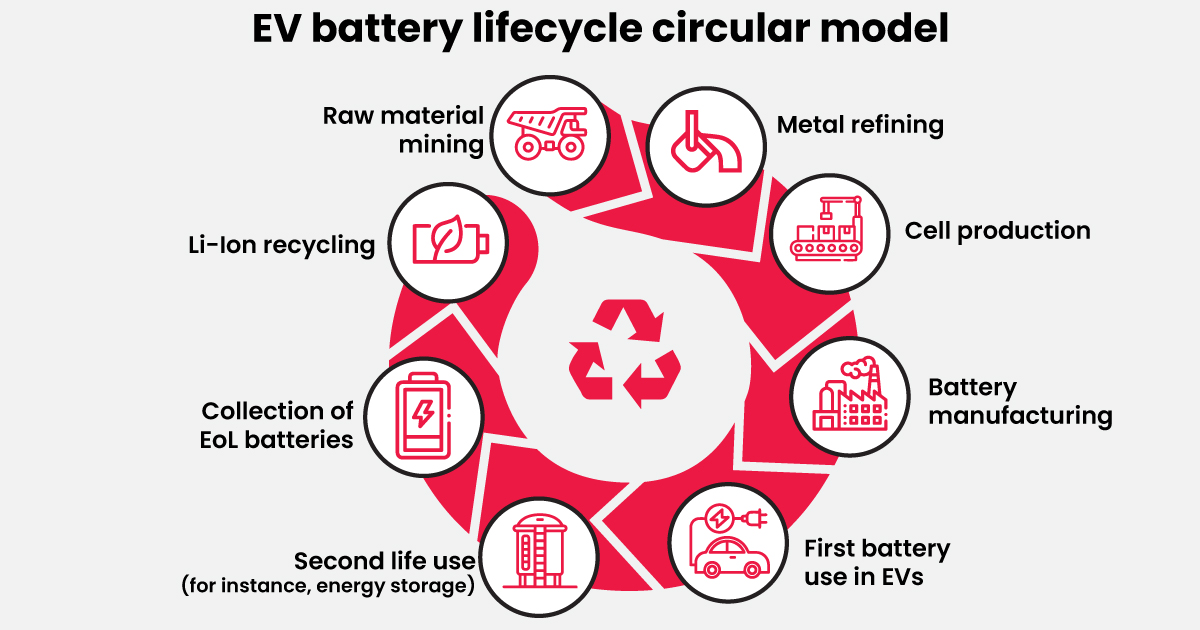

As more EVs are added to the world’s fleet of vehicles, massive quantities of expired EV batteries will require recycling so that their constituents can be used in the production of new batteries.

Market value projected for EV battery reuse and recycling activities globally between 2021 and 2026

To become part of a circular business model, EV Li-ion batteries must be effectively collected, handled, repurposed, and recycled. The industry, however, faces three main obstacles in its efforts to achieve sustainability:

1. Analyzing EV battery status and handling obsolete batteries

Examining the status of an EV battery is challenging since each battery contains a pack of battery cells. Basically, the owner of an EV should have access to a simple tool or available procedure to check the status of the car’s battery. It is important to study the life cycle of each battery so that its quality and charge can be evaluated in terms of the recycling market’s ability to handle it as effectively as possible.

For instance, batteries that still retain some capacity could be used as battery packs for mobile EV charging.

Batteries with little charge left in them can be broken down to enable raw materials, including lithium, nickel, and manganese, to be recovered from them. These can then be used in the production of new EV batteries. However, this is not as simple as it sounds.

2. High costs of collecting and managing EV batteries

Experts say that collecting every single battery is very costly. Furthermore, there has never been a comprehensive and accurate examination of the logistics of end-of-life (EoL) battery transportation. Figures for transportation expenses among the 17 studies that concentrate on EoL batteries range considerably, from over US$5/kg to less than 30 cents yet this expense accounts for, on average, 41% of the entire cost of recycling.

* End-of-life batteries are those that are unable to operate efficiently meaning they can no longer be used.

All phases of the battery value chain must be taken into account in order to achieve a truly renewable future.

3. Lack of standards

The multitude of producers and technologies currently involved in the production of EV batteries has resulted in a certain amount of chaos in the market, particularly for controlling bodies and policymakers. There is currently no one clear standard for tracking battery health, collecting the hardware, and managing the reverse logistics.

Without uniform standards, each business is required to devise unique specifications depending on the point at which batteries are no longer functional. Suppliers thus struggle to synchronize operations and services.

While EV batteries, therefore, remain outside the recycling loop, a collaborative effort for EoL battery management has been prioritized by automakers, car parts suppliers, and logistics firms via the Circular Cars Initiative.

The Circular Cars Initiative

The Circular Cars Initiative is one of the platforms that the World Economic Forum has created to address the issues related to the transition to a more sustainable economy.

The Initiative has given top priority to coordinated action for EoL battery management among car makers, car parts suppliers, and logistics firms. This includes:

- Transferring knowledge about expected EoL battery allocation, returns, and recycling.

- Looking into the possibility of sharing collecting centers for EoL batteries and pooling these together safely.

- Discussing what has been learned about how to classify, dismantle, fix, and recycle batteries.

Final word:

In the quest to achieve net zero, EVs have the potential to significantly reduce the world’s CO2 emissions via tailpipe savings.

However, if the automobile sector continues to make a significant manufacturing contribution in an attempt to satisfy the demand for batteries, this reduction will have a far smaller impact.

E-mobility will move more quickly towards a low-carbon future if it manages to complete the loop of using and recycling EV batteries where the components are examined, the whole operation is standardized, and profit is generated.

Suggested reading:

The major technology challenges to be aware of in 2023 and beyond

Top 5 future trends in business that companies need to be aware of

Share to